Use-case Manufacturing & Industrial Processes

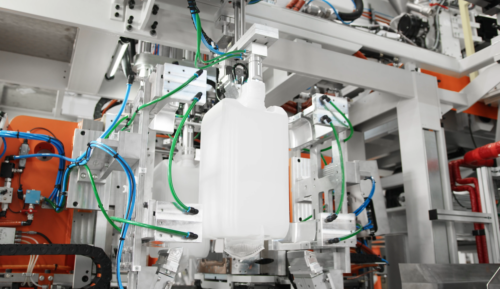

The tooling for blow molding machines involves the development and production of mold tools required to manufacture hollow plastic products such as bottles or containers. In the blow molding process, molten plastic is first extruded and then placed into a two-part mold before being inflated to fill the inner surfaces of the mold. After cooling and solidifying, the mold is opened, and the product is removed.

The quality of the final product heavily depends on the quality of the tooling used, making precision and quality in tooling crucial. The molds must meet specific requirements: they must have the right shape and size for the desired product, withstand the high pressures and temperatures of the blow molding process, and be designed for easy opening and closing to extract the finished product and repeat the process. These factors make blow molding tooling a challenging and precise discipline.