StrömungsRaum®

Better Decisions.

Simulation and AI-based solutions to enhance industrial innovation and business agility.

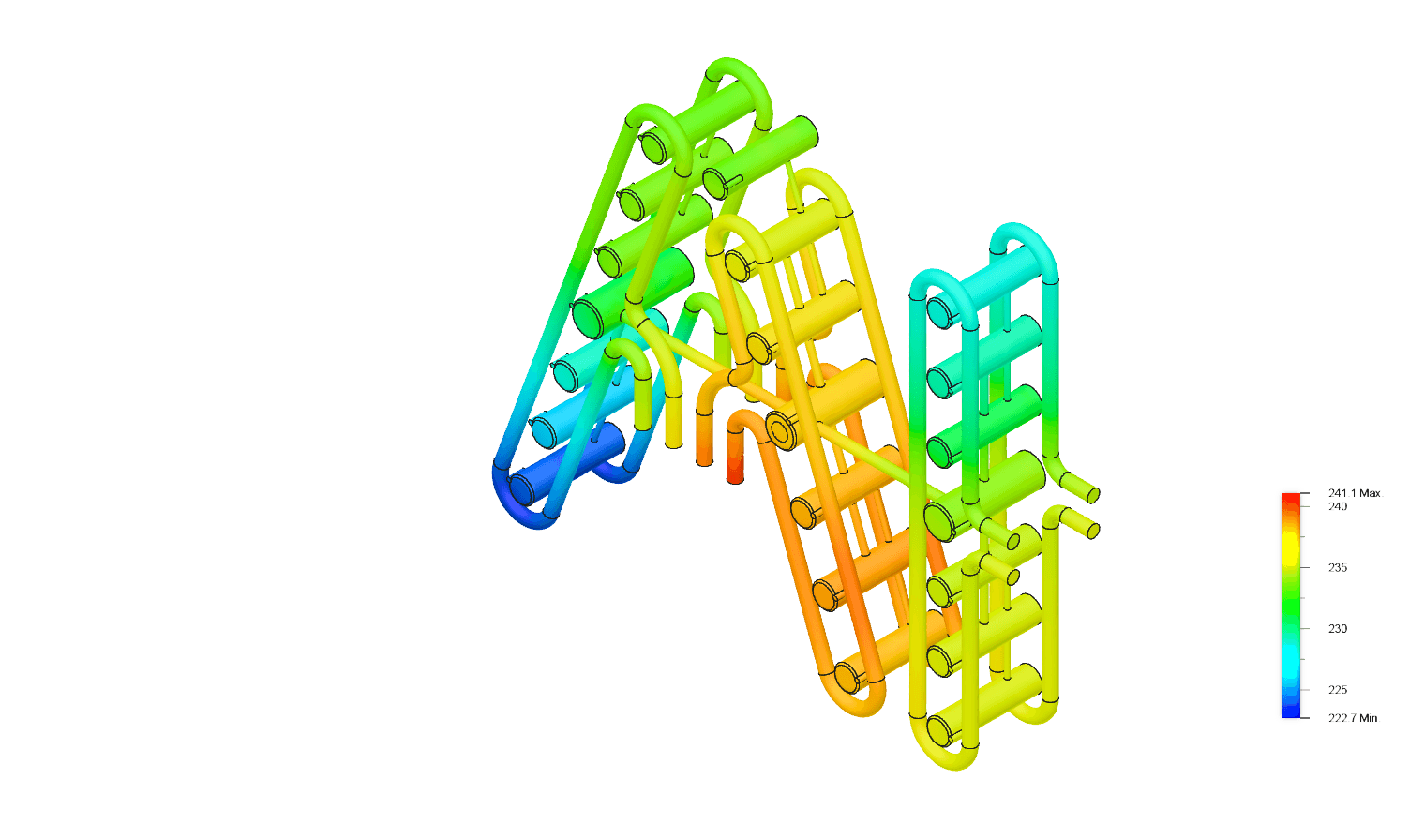

Precise and efficient simulations for informed decision-making

Flexible and cost-effective implementation without additional hardware

Custom integration supported by our expert team

Companies worldwide rely on our leading simulation solutions.

Rapid and easy optimization with StrömungsRaum®

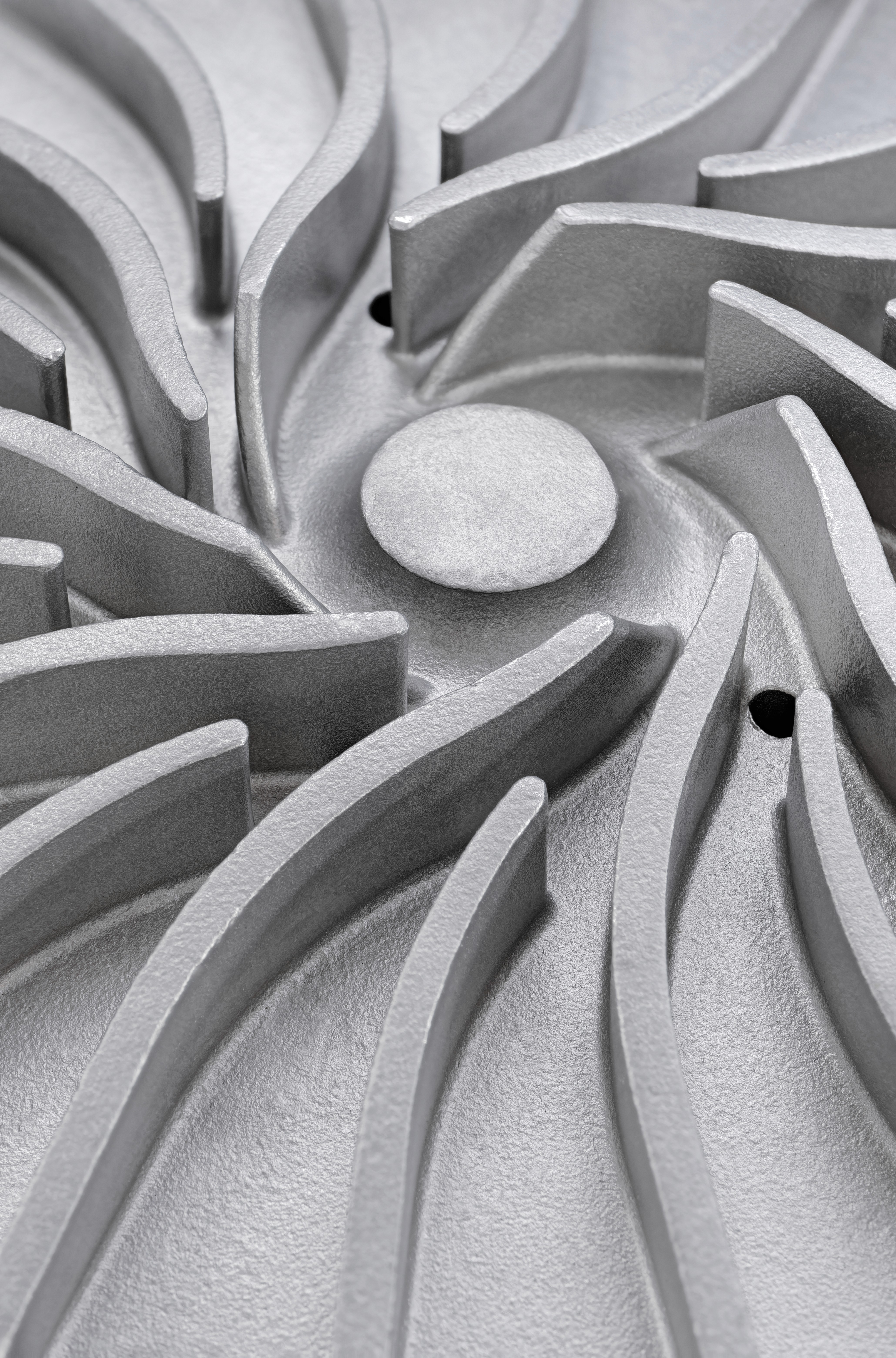

Optimize your processes in no time with StrömungsRaum®. Our user-friendly platform combines state-of-the-art simulation and AI technology to optimally support your specific requirements.

Comprehensive process optimization for maximum efficiency

StrömungsRaum® hilft Ihnen, Ihre Produktion und betriebliche Effizienz zu steigern. Die Plattform ermöglicht es, Innovationen schnell und kosteneffizient in Ihre Prozesse zu integrieren.

End-to-End Automation

Automate all your simulation and optimization processes—from data input to result analysis—thus minimizing manual tasks.

Scalable Cloud Infrastructure

Benefit from a cloud-based platform that flexibly adapts to your business growth without requiring costly hardware investments.

AI-driven optimization

Our AI algorithms enable precise analysis and optimization of your processes, allowing you to identify error sources early and reduce production costs.

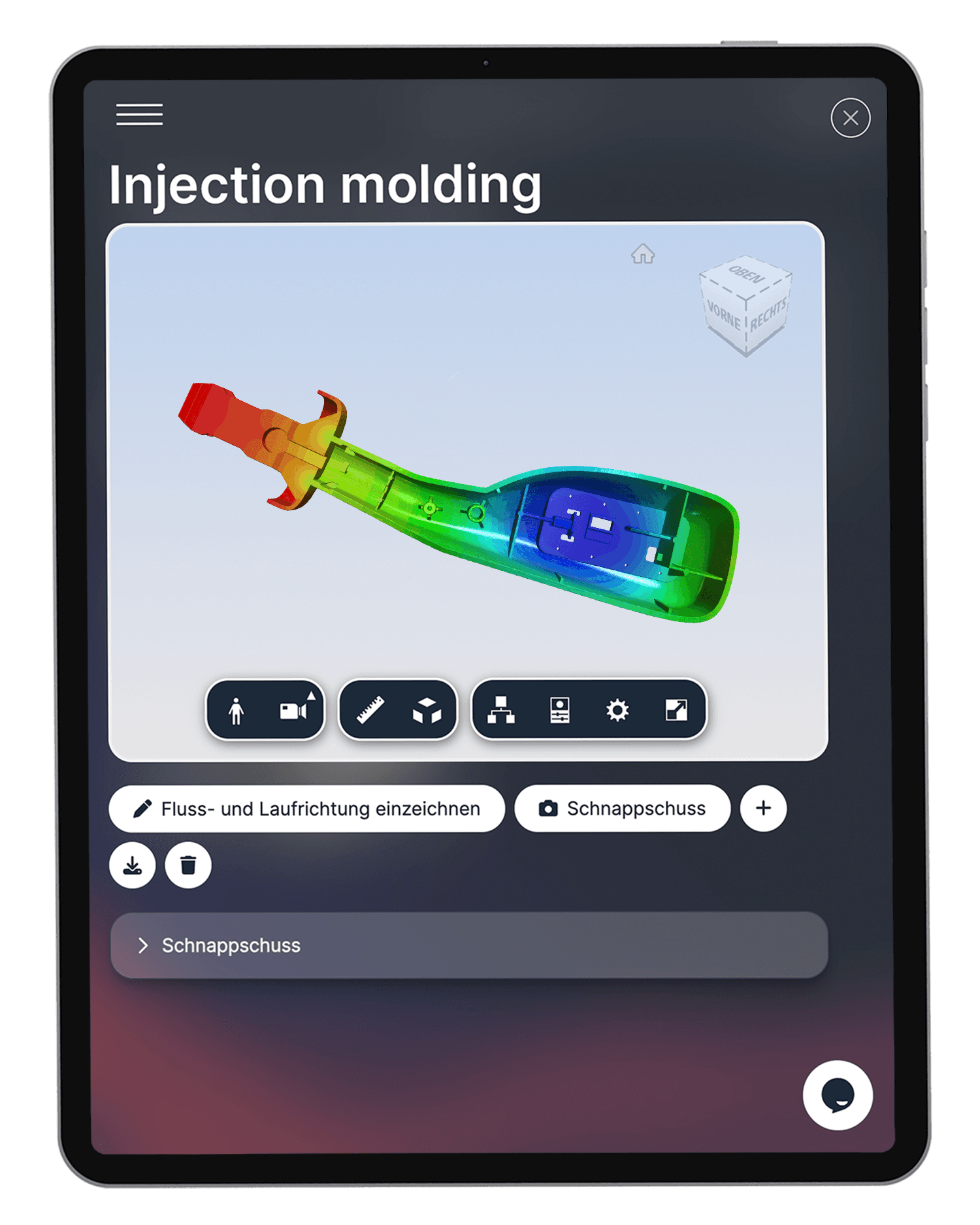

User-friendly interface

With its intuitive design and hyperautomation, you don't need extensive technical knowledge to fully leverage the platform's capabilities.

Real-time visualization and monitoring

Track your simulations and optimizations in real-time and make swift decisions based on up-to-date data.

Comprehensive Integration Capabilities

StrömungsRaum® can be seamlessly integrated into your existing systems and supports numerous industry standards, allowing you to start without any detours.

Products in StrömungsRaum®

Experience the versatility of StrömungsRaum® across various industrial sectors. Our solutions enhance the efficiency, quality, and agility of your production.

Seamless integration into your existing infrastructure

StrömungsRaum® allows for flexible integration that adapts to your existing systems. Leverage market-leading technologies to optimize your workflows and efficiently network your processes.

Whitelabel:

Your Platform, Our Technology

Do your customers understand how the processes behave with your products? Or are you still struggling with simulation data from suppliers in various formats and programs? Create clarity and invite your customers and suppliers to the new generation of the DigitalTwinSupplyChain.

With our white-label solution, your customers and suppliers can get to know StrömungsRaum® as a fully integrated simulation platform from your company and conduct simulations independently.

The results are recorded in a central database, establishing a uniform, comparable data standard for all customers and suppliers for the first time. This way, you maintain an overview of all relevant design and material data, eliminate fragmented data formats, and increase the efficiency of your entire supply chain.

Through the white-label solution, you provide your customers and suppliers with a seamless, accessible solution that enables innovation through simulation without bureaucratic or financial hurdles. Complete integration into your systems keeps your brand identity always at the forefront while upholding the highest security and data protection standards. The future of simulation is transparent, efficient, and seamlessly connected – and it starts with you.

Secure your access early now!

Our experts

Frequently Asked Questions (FAQ)

Responses to the most common questions about StrömungsRaum®.

StrömungsRaum® has been developed to flexibly and securely meet all the demands of modern industry. Our support team accompanies you every step of the way to ensure seamless integration and optimal use.