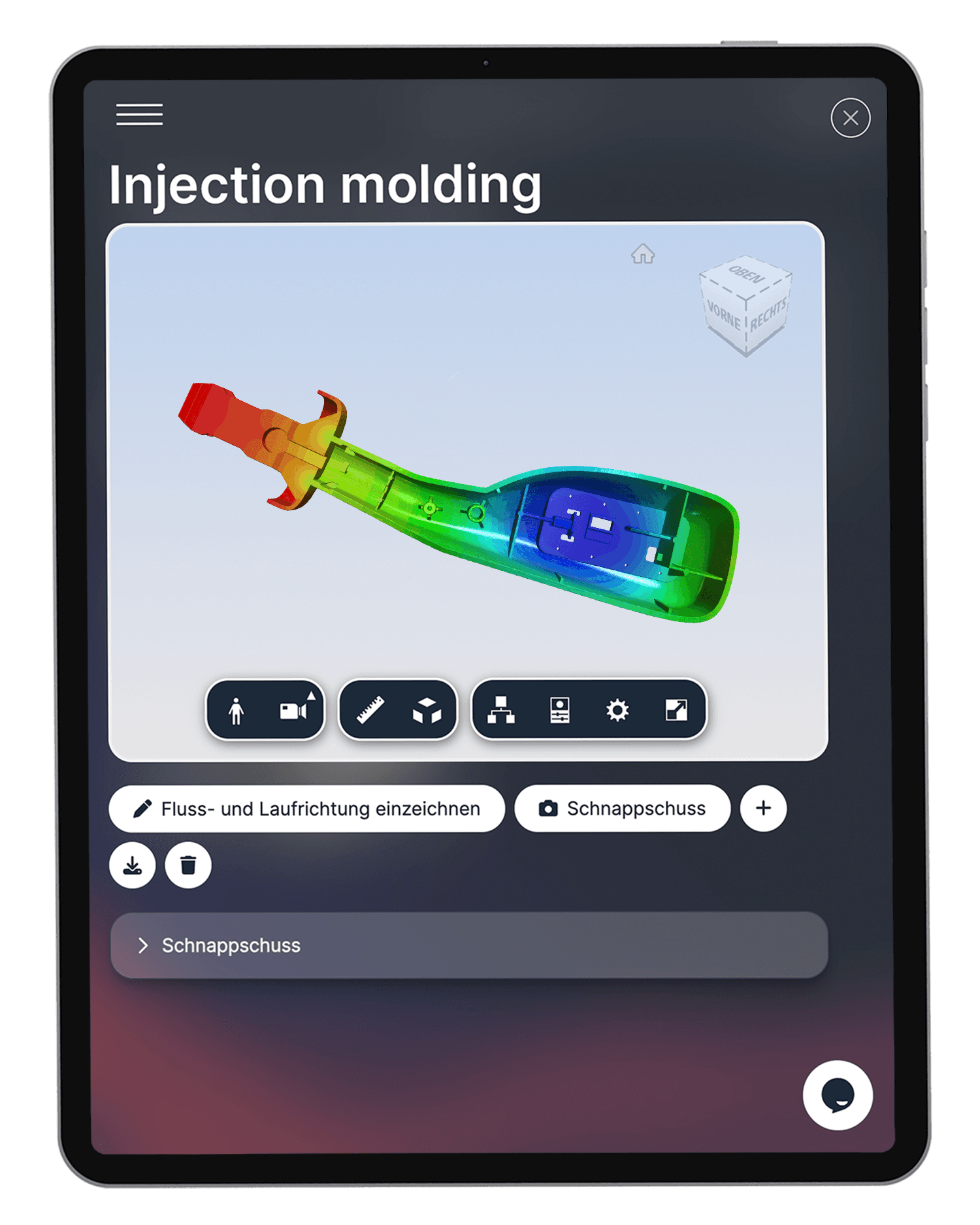

A comprehensive simulation solution for precise, efficient, and error-free injection molding processes

Reach a new level of process optimization with StrömungsRaum®. Our simulation platform supports you through state-of-the-art numerics and tailored solutions that enhance your production quality while saving time and costs.

Powered by IANUS Simulation

Numerous top companies utilize StrömungsRaum® to optimize their injection molding processes

Customized solutions and collaboration at eye level

StrömungsRaum® – Your Custom Solution for All Injection Molding Requirements

Our platform is specifically developed for the challenges and needs of the injection molding industry. FlowSpace® provides you with high-precision simulations and an experienced team to support you in sustainably improving your processes and strengthening your market position.

IANUS Simulation in Kunststoffe.de Magazine

IANUS Simulation enhances the innovation potential of the plastics industry!

The StrömungsRaum® framework by IANUS Simulation facilitates simulation-based optimizations without requiring prior knowledge or hardware, sustainably saving resources and enhancing process efficiency to the advantage of your enterprise.

Master complex processes without costly iterations

FlowSpace® enables complete process simulations from polymer production to injection molding and reduces real-life test runs.

Minimize time and material waste

With StrömungsRaum®, companies can identify weaknesses early, shorten development times, and reduce costs.

No professionals? StrömungsRaum® enables simulations without expert knowledge.

Easily operable cloud simulations optimize processes and reduce reliance on specialists.

Customized solutions and collaboration at eye level

Leverage the comprehensive advantages of the StrömungsRaum® simulation to stand out from the competition:

Unmatched Precision through Advanced 3D-CFD Analysis

Our simulations capture the material flow and temperature distribution in your injection molding tools in detail. This minimizes waste and rework, ensuring consistent quality.

Cost Savings through Error Prevention

StrömungsRaum® assists you in identifying and rectifying potential errors at an early stage, thereby reducing costly rework. The result: More efficient production with less waste.

Accelerated Development Cycles

Reduce the development time of new products through real-time simulations and targeted optimizations. This way, your innovations reach the market faster, providing you with a clear competitive advantage.

Practical Results.

Better Decisions.

Comprehensive support – from planning to successful implementation

StrömungsRaum® – Complete Solution for Your Projects

With StrömungsRaum®, you have a solution that supports you at all levels of your projects:

Customized Training and Support

Let your team be trained by our experts to fully leverage the potential of injection molding simulations.

Exclusive Insights and Upgrades

Stay technologically up-to-date and access the latest developments and updates.

Collaborative Development Projects

Experience continuous process improvements and innovations through joint projects that differentiate your products in the market.

Fill and Feasibility Analysis – Comprehensive Solution for Your Projects

Comprehensive Support – From Planning to Successful Implementation

With our fill and feasibility analysis, you have a solution that supports you at all levels of your projects, ensuring efficient and reliable results.

Detailed simulation results and comprehensive analysis

Utilize precise simulation data concerning fill time, pressure distribution, and temperature profile to identify potential challenges early and enhance efficiency.

Optimization of Component Quality and Process Reliability

Identify potential problem areas such as weld seams and air inclusions in advance, and minimize material stress to ensure optimal component quality.

Custom adjustments and consultation by experts

Our team is at your service for specific project requirements and supports you with tailored solutions for optimal results and product quality.

Stronger Together:

StrömungsRaum® & SimForm

StrömungsRaum® by IANUS Simulation and SimForm by MAYA HTT

are pleased to announce a new technology partnership that combines two complementary simulation platforms into a connected workflow for injection molding analysis.

This collaboration integrates IANUS Simulation's advanced capabilities for filling simulation, packing, and warpage with SimForm's Fast, easy, and affordable cooling simulation, enabling engineers to analyze, optimize, and validate part and mold designs with greater accuracy and efficiency.

An Overview of Your Advantages

Maximize Your Potential in Injection Molding Production with StrömungsRaum®

StrömungsRaum® enhances your injection molding processes through a comprehensive solution specifically tailored for the industry. Here are three key advantages:

Gain access to a comprehensive simulation department, tailored to your individual requirements, for less than €30,000 per year.

Our experts act as an extension of your team, helping you reduce development times and enhance quality.

In addition to simulations, we offer flexible consulting hours for design assistance, process optimization, and technical queries.

Leverage over 100 hours of specialized consulting to access expert knowledge without developing your own resources.

Our high-performance clusters provide you with access to over 500,000 simulation hours per year, eliminating the need for your own hardware. Effortlessly scale your projects without any additional cost.

Flexibility, efficiency, and comprehensive support for your injection molding processes

Flexibility

Utilize simulation resources when and where you need them. Additional hours can be added at any time.

Concurrent Processing

Thanks to our high-performance clusters, multiple departments can simultaneously benefit from simulations.

Cost Efficiency

A complete simulation department at a fraction of the cost for hardware, software, and personnel.

Continuous Optimization

Utilize simulation results for long-term process improvements.

You bring the problem - we handle the rest.

Our team takes care of all the details of the simulation, so you can

focus on your core business.

StrömungsRaum® Injection Molding – Your Comprehensive Solution Without Compromises

With StrömungsRaum®, you get a complete, flexible, and cost-effective simulation department without having to build your own resources. Ideal for companies that prioritize efficiency, scalability, and continuous improvement.

Comprehensive Service from a Single Source: From consultation to implementation – we are there for you.

Maximum Flexibility: Simulations exactly when you need them.

Simultaneous Project Processing: Address multiple challenges in parallel.

Cost Efficiency: Fixed prices for all required resources and services.

No hardware needed: Use our high-performance clusters instead of your own hardware.

Continuous Optimization: Leverage simulation results for long-term process improvements.